Recently, the EU MSCA-ETN SULTAN project has initiated its research on the reprocessing of tailings. To explain the research goals to a wide audience, the ETN SULTAN team has just released its official video. In this animated video SULTAN Researcher Jillian Helser explains how the SULTAN target is to transform mining waste (tailings) into valuable products. As was the case for several other award-winning ETN videos (cf. DEMETER), this new video was produced in cooperation with Storyrunner. (PTJ, Leuven, 21/6/2019).

The SULTAN project

As documented in the ETN SULTAN video (watch here), for more than 100 years the EU mining industries have been discarding their extractive-waste residues. Estimates suggest this represents 29% of the EU-28’s current waste output. When poorly managed these residues are a significant environmental hazard. Sulfidic Cu-Zn, Zn-Pb and Cu-Zn-Pb tailings pose the largest challenge, as they are prone to acid mine drainage. However, these tailings also contain valuable metals. Recently, the European Innovation Partnership (EIP) on Raw Materials launched a “call to arms” to transform the “extractive-waste problem” into a “resource-recovery opportunity”.

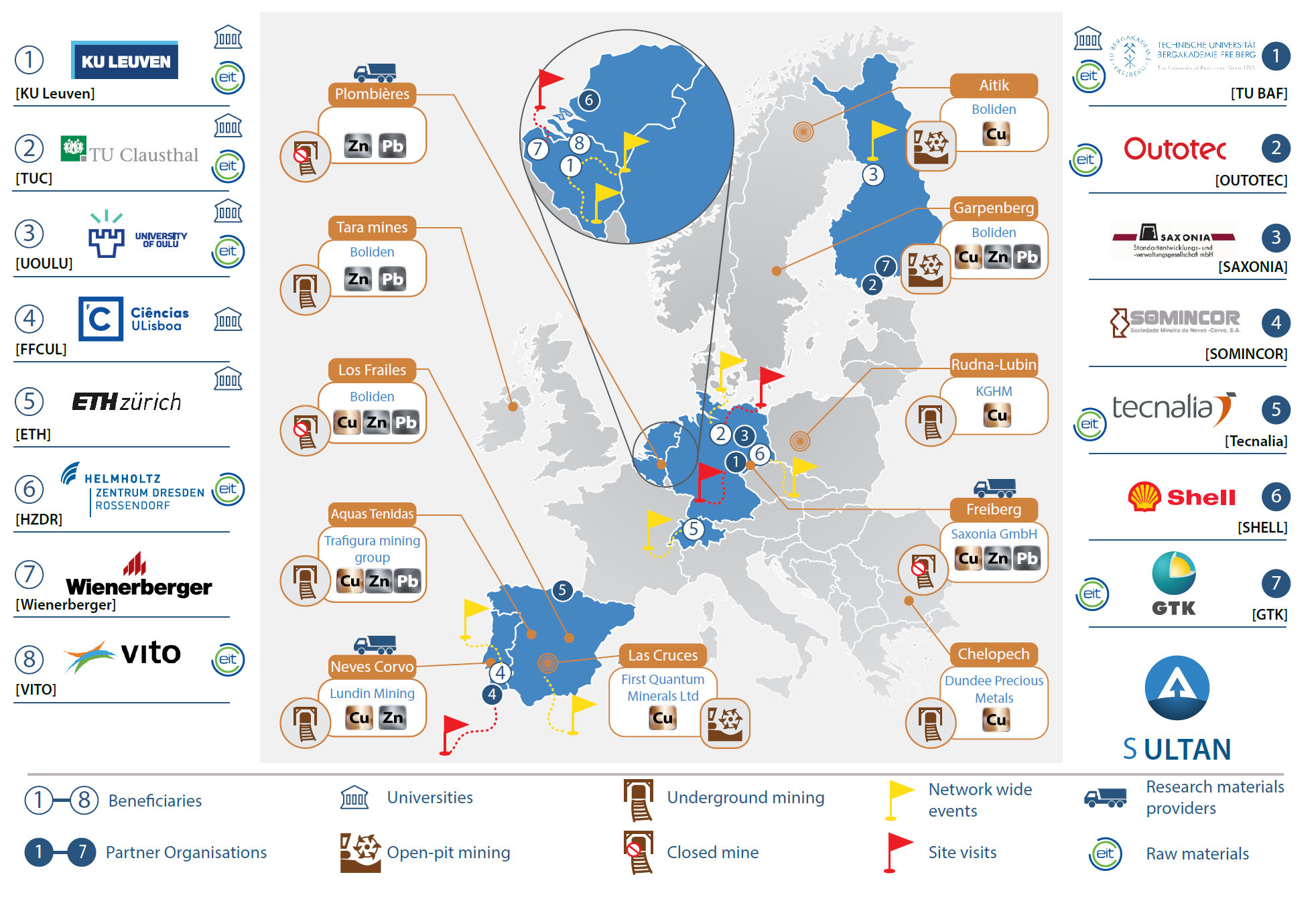

Additionally, the EIP has warned about the acute shortage of talent in this sector. In order to develop a highly skilled workforce, to mitigate environmental risks and to economically recover valuable raw materials, the ETN for the remediation and reprocessing of sulfidic mining waste sites (SULTAN) provides the first-ever training programme dedicated to the reprocessing of tailings. SULTAN has pooled the interdisciplinary and intersectoral expertise of leading EIT RawMaterials members, world-leading mining and chemical companies, covering all the links in the tailings-reprocessing value chain.

SULTAN develops cutting-edge methodologies to assess the resource potential of Europe’s main tailings families (WP1) and explores eco-friendly mining chemicals to be used in advanced metal-extraction/recovery set-ups (WP2). SULTAN not only recovers the metals but also valorises the clean(ed) tailing residues in circular-economy applications, incl. inorganic polymers, green cements and ceramics (WP3). In WP4 a novel environmental assessment methodology is developed.

The 15 SULTAN ESRs also benefit from a unique soft-skills training programme (WP5) and maximise the impact of their research through dissemination and exploitation (WP6). This will kick-start their careers as highly employable professionals in the EU’s tailings reprocessing/remediation sector, as well as for geological surveys, teaching and scientific organisations, and public bodies.

The SULTAN Consortium

The SULTAN team is made up of 8 Beneficiaries and 7 Partner Organisations, who collectively provide the first-ever training programme dedicated to the reprocessing of tailings for 15 researchers from 11 countries and 5 continents. SULTAN is coordinated by SIM² KU Leuven. You can read more about the team here.

Acknowledgements

This project has received funding from the European Union’s EU Framework Programme for Research and Innovation Horizon 2020 under Grant Agreement No 812580.