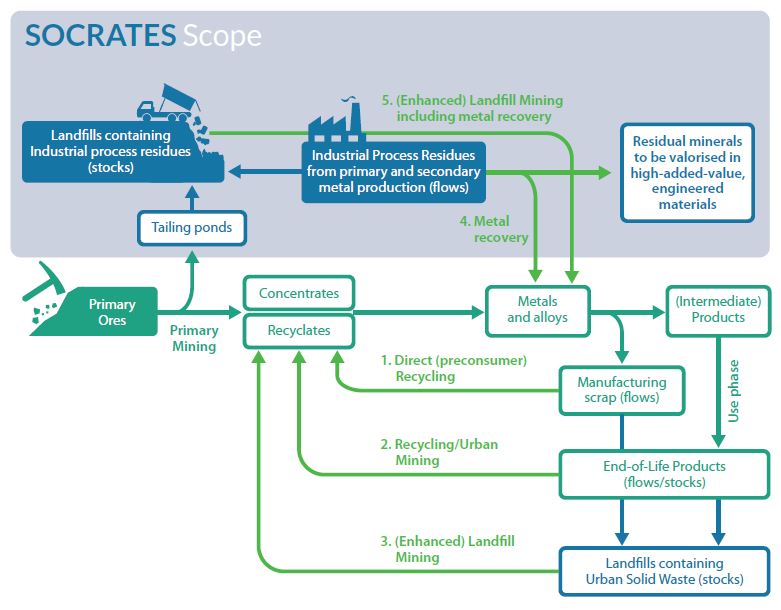

The European Training Network for the Sustainable, zero-waste valorisation of critical-metal-containing industrial process residues (SOCRATES) targets ground-breaking metallurgical processes, incl. plasma-, bio-, solvo-, electro- and ionometallurgy, that can be integrated into environmentally friendly, (near-)zero-waste valorisation flow sheets. By unlocking the potential of these secondary raw materials, SOCRATES contributes to a more diversified and sustainable supply chain for critical metals (cf. Priority area 3 in EC Circular Economy Action Plan; COM(2015)614/2). The SOCRATES consortium brings together all the relevant stakeholders along the value chain, from metal extraction, to metal recovery, and to residual matrix valorisation in added-value applications, such as supplementary cementitious materials, inorganic polymers and catalysts. To maximise applicability, SOCRATES has selected four commonly available and chemically complementary residue families: (1) flotation tailings from primary Cu production, (2) Fe-rich sludges from Zn production, (3) fayalitic slags from non-ferrous metallurgy, and (4) bottom ashes from incineration plants. As a basis for a concerted effort to strengthen the EU’s critical-metal supply chain for Ge, In, Ga and Sb, SOCRATES trains 15 early-stage researchers (ESRs) in technological innovation: metal extraction (WP1), metal recovery (WP2), residual matrix valorisation (WP3) and integrated assessment (WP4). By training the ESRs in scientific, technical and soft skills, they are the next generation of highly employable scientists and engineers in the raw-materials sector.

The ETN SOCRATES runs for four years from September 1, 2016 to August 31, 2020.

Four technical work packages are reviewing the different aspects of zero-waste valorization of industrial process residues:

- Metal extraction

- Metal recovery

- Residual-matrix valorization

- Advanced characterization, mapping & integrated assessment of flow sheets

Work package 1: metal extraction. In work package 1, four ESRs develop novel metal extraction technology for industrial process residues. Specifically, biocompatible solvometallurgical (ESR1) and ionometallurgical (using deep eutectic solvents, DESs) leaching methods (ESR2) are developed for the recovery of critical and economically important metals from low-grade industrial-process residues (tailings, Fe-rich sludges, slags and ashes); A plasma plasma-driven process is studied for metal recovery from slags (ESR3); a hydrometallurgical process, based on chloride leaching, is developed for metal recovery from complex impure process solutions (ESR4). For each metal extraction technology, a flowsheet has been developed linking the technology with metal recovery technologies (WP2) and mineral valorisation technologies (WP3) to be able to deliver near-zero-waste approaches for the in scope residues.

Work package 2: metal Recovery. Work package 2 treats the recovery of metals from leaching solutions. Six ESRs work in this work package. Specifically the following topics are studied: electrowinning of metals from DESs (ESR5); electrowinning of metals from complex impure chloride solutions (ESR6); non-aqueous solvent-extraction processes in milliflow reactors (ESR7); synthesis of extractants and ionic-liquid diluents from renewable chemicals (ESR8); miscibility of organic solvents, for the prediction of suitable solvent pairs for non-aqueous solvent extraction (studied using computational methods, ESR9); in-silico design of selective extractants for metal ions (ESR10).

Work Package 3: Residual matrix valorisation. Work package 3 treats residual mineral matrix valorisation after metal extraction. Three processes are being studied, being synthesis of cement (ESR11), inorganic polymers (ESR12) and as catalysts (ESR13). The aim is to valorise the residual mineral matrices (after metal extraction) from industrial-process residues (tailings, sludges, slags and ashes) as supplementary cementitious materials with calcium aluminate binders (ESR11), and/or iron-rich inorganic polymers (ESR12), and/or heterogeneous catalysts (ESR13).

Work package 4: Advanced characterization, mapping and integrated assessment of flowsheets. Work package 4 studies the advanced characterization of complex industrial residues (identification and distribution of the phases containing critical metals) and develops an integrated assessment of the flow sheets in the project. The assessment involves systems-analysis methods for assessing key economic, environmental, technical, market and policy conditions and measures for the realisation of critical-metal recovery and valorisation flow sheets. While individual processes of the ESRs are being assessed, 3 flowsheets from the project were selected for performing an assessment on a flowsheet level.

Progress beyond the state of the art

SOCRATES targets the development of novel metallurgical processes, that can be integrated into environmentally friendly, near-zero-waste valorisation flowsheets. By unlocking the potential of several industrial residues – currently waste – SOCRATES contributes to a more diversified and sustainable supply chain for base, valuable and critical metals. Spill-over of technologies to materials outside the scope of SOCRATES (E.g. primary ores, high grade materials, electronic scrap) is considered to be natural. Project results have been communicated and disseminated widely (publications, policy briefs, different video’s, etc.). The SOCRATES project film was viewed, shared and liked massively on social media (over 10.000 views on Facebook alone). It can be viewed online on YouTube on: https://www.youtube.com/watch?v=9ilrNeKG4D8

SOCRATES provides training in all aspects of near-zero-waste recycling of low-grade residues, not only to ESRs but also to all consortium members and external partners (e.g. through summer school). The SOCRATES consortium brings together all the relevant stakeholders along the value chain, from metal extraction, to metal recovery, and to residual matrix valorisation in added-value applications, such as supplementary cementitious materials, inorganic polymers and catalysts. SOCRATES ESRs are the logical employees for these sectors and contact with future employers is guaranteed already during the project through the presence of these actors within the consortium and in the broader network.

SOCRATES is well embedded in/ and actively contributes to the growth of the network on near-zero-waste recycling. A strong link to national/E.U. initiatives ensures the long-term sustainability of the network. Continuation of the network is ensured by active participation in conferences and events in the field, the organisation of the SOCRATES symposium and continued organisation of Summer Schools, engagement in upscaling of SOCRATES technologies, e.g. “KAVA activities” (KIC Added Value Activities) within EIT KIC Raw Materials & InnoEnergy and EIA/RIA projects in the field.